Introducing an Extensive Choice of Long Lasting Undercarriage Parts for Heavy Machinery

Introducing an Extensive Choice of Long Lasting Undercarriage Parts for Heavy Machinery

Blog Article

Make Best Use Of Performance With Long Lasting Undercarriage Parts

In the world of hefty machinery and devices, the function of undercarriage components is paramount in guaranteeing ideal efficiency and longevity. The performance and performance of these components can dramatically influence the overall operation of equipment, making the option of resilient undercarriage parts an essential decision for drivers and managers alike.

Advantages of Making Use Of Sturdy Undercarriage Components

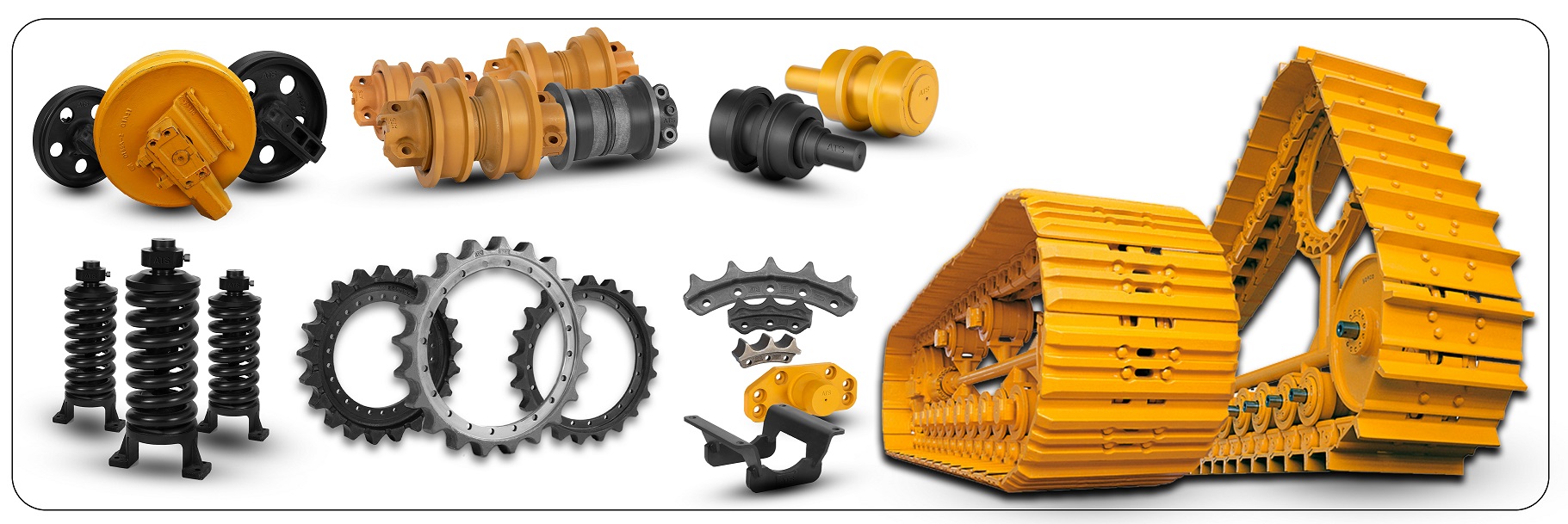

Using durable undercarriage components not just boosts the long life of heavy equipment however additionally reduces upkeep expenses significantly. By investing in top quality undercarriage elements, such as tracks, idlers, rollers, and gears, devices drivers can experience boosted uptime and boosted total efficiency.

Furthermore, the durability of heavy equipment is directly linked to the quality of its undercarriage parts. Sturdy elements can hold up against the roughness of requiring applications, making sure that the equipment remains functional for extensive durations. Because of this, drivers can prevent costly downtime and upkeep expenditures, eventually making best use of the return on financial investment for their equipment.

Factors Influencing Undercarriage Toughness

The resilience of undercarriage parts in heavy equipment is affected by numerous important factors that directly influence performance and longevity. Among the crucial aspects affecting undercarriage resilience is the top quality of products made use of in manufacturing. Top notch products, such as hard steel, are necessary for holding up against the severe conditions and heavy lots that undercarriage parts are subjected to. Proper upkeep methods also play an essential role in figuring out the lifespan of undercarriage components. Normal assessments, lubrication, and prompt replacement of damaged components can substantially expand the resilience of the undercarriage.

In addition, ecological aspects can have a considerable effect on the longevity of undercarriage components. Exposure to unpleasant materials, severe temperatures, and severe working conditions can increase wear and tear on undercarriage parts. As a result, selecting undercarriage components that are particularly developed to withstand these ecological challenges is essential for making certain toughness.

In addition, the layout and engineering of undercarriage parts have a straight impact on their durability. Parts that are created to disperse loads uniformly, minimize rubbing, and lessen stress concentrations are more likely to have a longer lifespan - undercarriage parts. By thinking about these vital variables, equipment operators can maximize the longevity and performance of their undercarriage components

Upkeep Tips for Lengthening Undercarriage Life

Executing routine maintenance regimens is necessary for extending the lifespan of undercarriage elements in heavy equipment. To prolong the undercarriage life, it is essential to often inspect for deterioration. Frequently look for loosened or absent bolts, harmed rollers, or misaligned tracks, as these problems can intensify and trigger more damage if not resolved promptly. Furthermore, guarantee that the undercarriage is appropriately lubricated according to producer standards to decrease rubbing and avoid early wear.

Another essential upkeep pointer is to keep the undercarriage tidy from dust, rocks, and debris. Buildup in the undercarriage can accelerate wear and corrosion, bring about expensive repairs. Cleaning the undercarriage after operation in extreme conditions is advised to stop these problems.

Last but not least, tracking and recording maintenance activities can help in creating an aggressive upkeep schedule. Maintaining in-depth records of replacements, repair services, and assessments can offer important understandings right into the undercarriage's problem and efficiency in time, assisting in forecasting and stopping prospective failings. By complying with these upkeep suggestions carefully, drivers can significantly enhance the sturdiness and efficiency of undercarriage parts in heavy equipment.

Choosing the Right Undercarriage Components

Choosing proper undercarriage parts is crucial for making best use of the efficiency and longevity of heavy machinery. When it involves picking the right undercarriage components, there are advice several elements to think about. One key factor is recognizing the details needs of the equipment and the setting in which it will certainly run. Various applications might require different sorts of undercarriage components, such as tracks, gears, idlers, and rollers. It is vital to pick components that are designed to stand up to the specific conditions the maker will come across, whether it be rough surface, unpleasant materials, or extreme temperatures.

In addition, thinking about the high quality and credibility of the maker is crucial. Going with respectable brands known for creating high-performance and resilient undercarriage parts can substantially affect the total performance and long life of the machinery. Making certain that the parts are compatible with the maker version and properly set up is critical for optimal performance. By meticulously selecting the ideal undercarriage parts, equipment owners can improve performance, reduce downtime, and prolong the life expectancy of their hefty machinery.

Instance Researches: Enhanced Performance With Sturdy Components

Integrating resilient undercarriage components has demonstrated substantial enhancements in equipment performance. One case research entailed a building business that upgraded its excavator's undercarriage parts to a lot more long lasting alternatives. The company observed a remarkable reduction in downtime because of undercarriage upkeep, leading to raised performance and price savings. The durable components held up against severe working problems, lowering deterioration substantially.

In another circumstances, a mining procedure replaced the undercarriage parts of its bulldozer with high-quality, long lasting choices. This switch caused a remarkable enhancement in the excavator's ability to move and overall performance. The device might browse tough terrains much more successfully, leading to enhanced operational effectiveness and minimized gas usage.

Additionally, a logging business invested in durable undercarriage components for its forestry devices. These case studies underscore the substantial advantages of using long lasting undercarriage parts in enhancing equipment efficiency and long life.

Conclusion

To conclude, making use of resilient undercarriage components can considerably improve efficiency and durability of heavy machinery. check out here Elements such as proper upkeep and selecting the right parts play a crucial duty in taking full advantage of undercarriage toughness. By applying these methods, companies can lower downtime, boost efficiency, and eventually minimize functional costs. Study have actually shown that purchasing resilient undercarriage components can result in boosted overall efficiency and productivity in numerous industries.

The effectiveness and pop over to this site performance of these components can substantially affect the overall operation of machinery, making the option of sturdy undercarriage parts a vital choice for supervisors and drivers alike.Incorporating resilient undercarriage parts has shown significant enhancements in machinery performance. These situation research studies emphasize the substantial benefits of using resilient undercarriage parts in enhancing machinery performance and durability.

In verdict, making use of durable undercarriage parts can significantly improve performance and durability of heavy machinery (undercarriage parts). Case studies have shown that spending in resilient undercarriage components can lead to boosted general performance and performance in numerous sectors

Report this page